Product Details

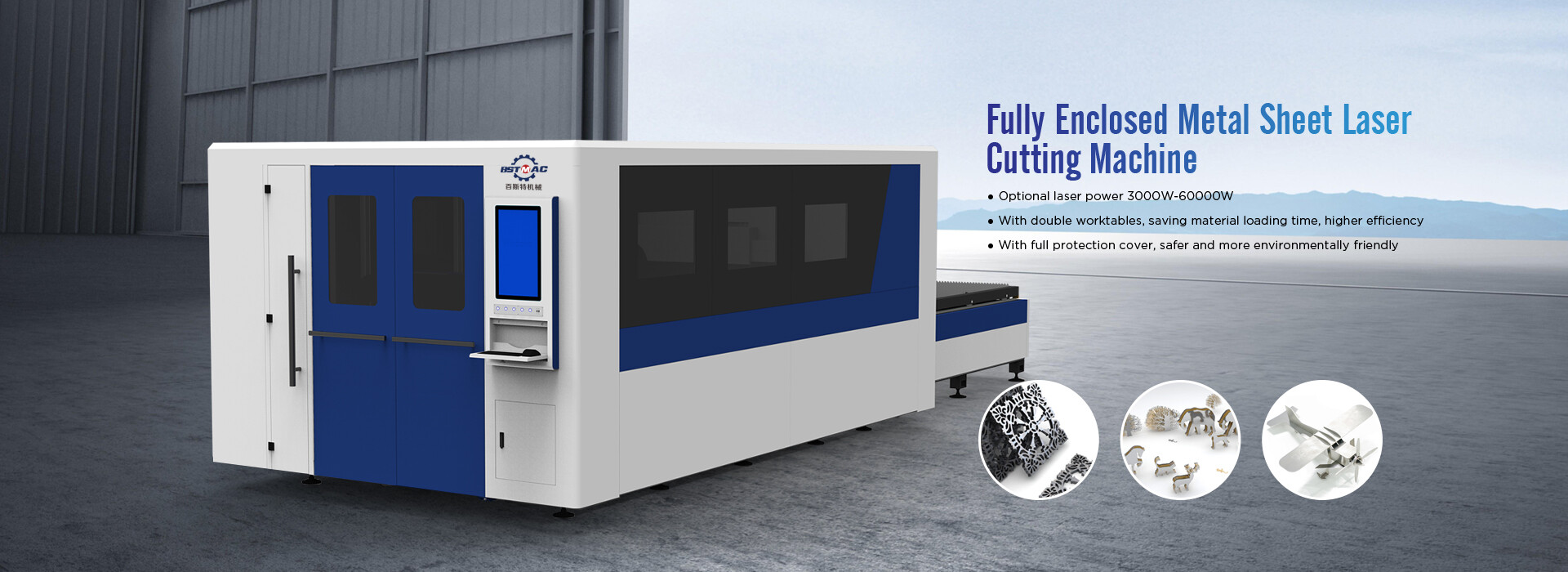

Fully-enclosed Super High Power Metal Sheet Laser Cutting Machine With Double Tables

Machine features

High performance laser device associated with stable operation system enables optimal cutting effects.

2.Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3.Double worktables make plates loading and unloading available during cutting, which improves the processing efficiency.

4.Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5.Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6.Gantry structure and inblock aluminum cast cross beam make the equipment rigid, stable and antiknock.

7.It could cut metal in various materials and realize excellent and stable cutting effects.

Technical parameters

|

Model |

BST-G3015T |

|

Optional laser power |

12000W-80000W |

|

Working size |

3000*1500mm/ 4000*2000mm/ 6300*2500mm/ 8000*2500mm |

|

Max. moving speed |

140m/min |

|

Max. acc. speed |

1.8G |

|

Positioning accuracy |

±0.03mm/m |

|

Repositioning accuracy |

±0.03mm |

|

Cooling system |

Water cooling |

|

After-sales service |

Engineers available to provide service overseas |

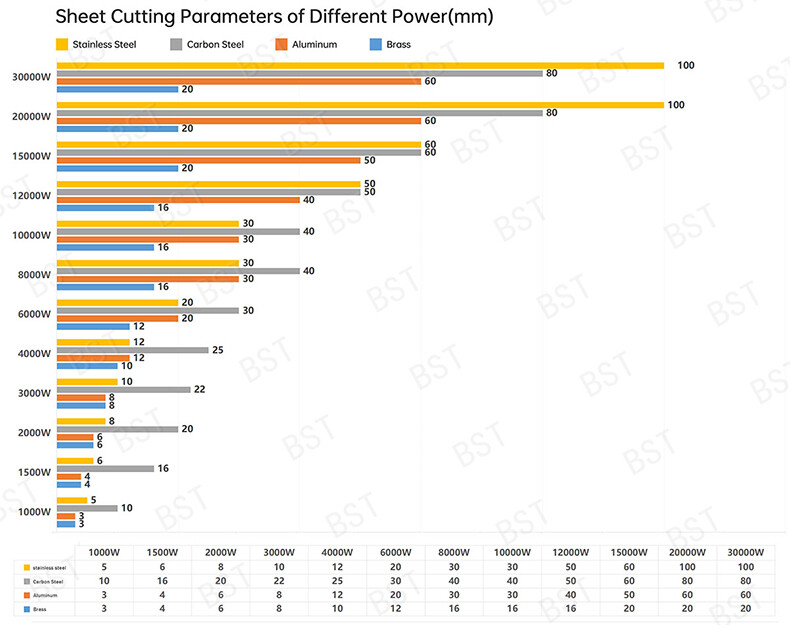

Cutting Thickness Parameters:

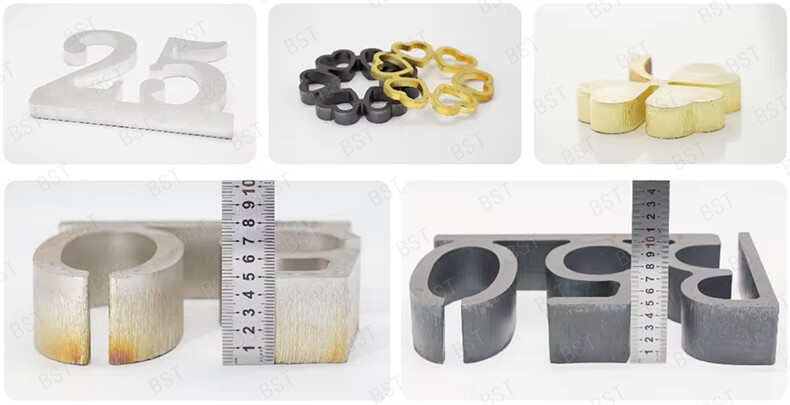

Applications and Cutting Samples:

Fiber laser cutting machines are gradually playing an important part in the metal fabrication industry. Such as metal signage, interior decoration, engineering parts, sheet metal cabinets, automobile industry, advertising industry, kitchenware industry, home appliance, elevators, doors and windows, and other industries.

Almost all materials common in the metal processing industry, steel, aluminum alloy, carbon steel, mild steel, galvanized steel, steel coil, zinc coated steel sheet, brass, stainless steel, electrolytic plate, and other ferrous and non-ferrous metals can be fastly and accurately cut by the laser cutting machine.

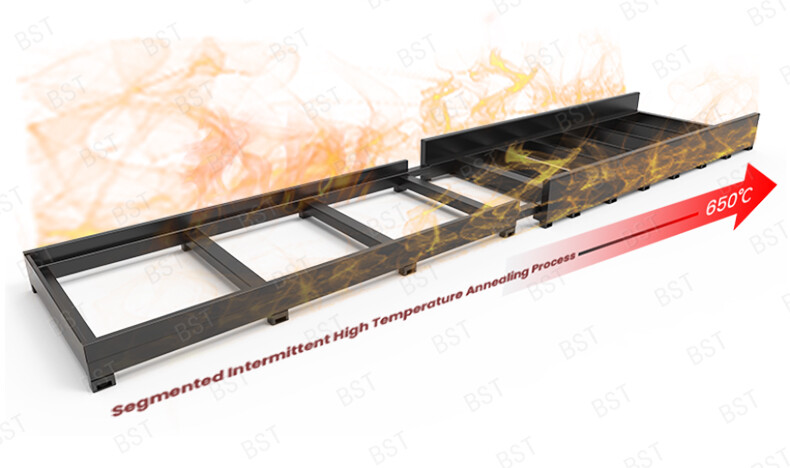

Independent R&D of Machine Bed

> Adopt industrial-grade standard annealing process to ensure the durability of the bed.

> After multiple precision manufacturing processes and testing, it ensures stable operation without deformation and long service life.

> With exclusive technology, it truly achieve high-speed interchange, ultra-smooth operation and ultra-high cutting efficiency.

Super Intelligent Bus Control System

> Easy operation

> Rich functions

> Excellent performance

Intelligent 10000W Cutting Head with 12 Sets of Intelligent Sensors

> The status of the cutting head can be monitored in real time.

> Unique anti-collision design to avoid collision loss

> Modular design to make maintenance more convenient

The Sixth Generation Aviation Aluminum Crossbeam

> Adopt aviation aluminum extrusion one-piece die-casting process

> Super dynamic performance

> Super high cutting precision

> Perfect realization of high-speed cutting

Quality Control

Machine body testing is important for checking quality of a laser machine, especially motion parts installation, which ensure running and cutting accuracy, here we introduce you how we test our laser machine.

1. Linear guide parallelism examination, our requirement ≤±0.02mm.

2. Rack installation, accuracy lower than ≤±0.02mm.

3. Guide gap detection, our requirement ≤±0.03mm.