Product Details

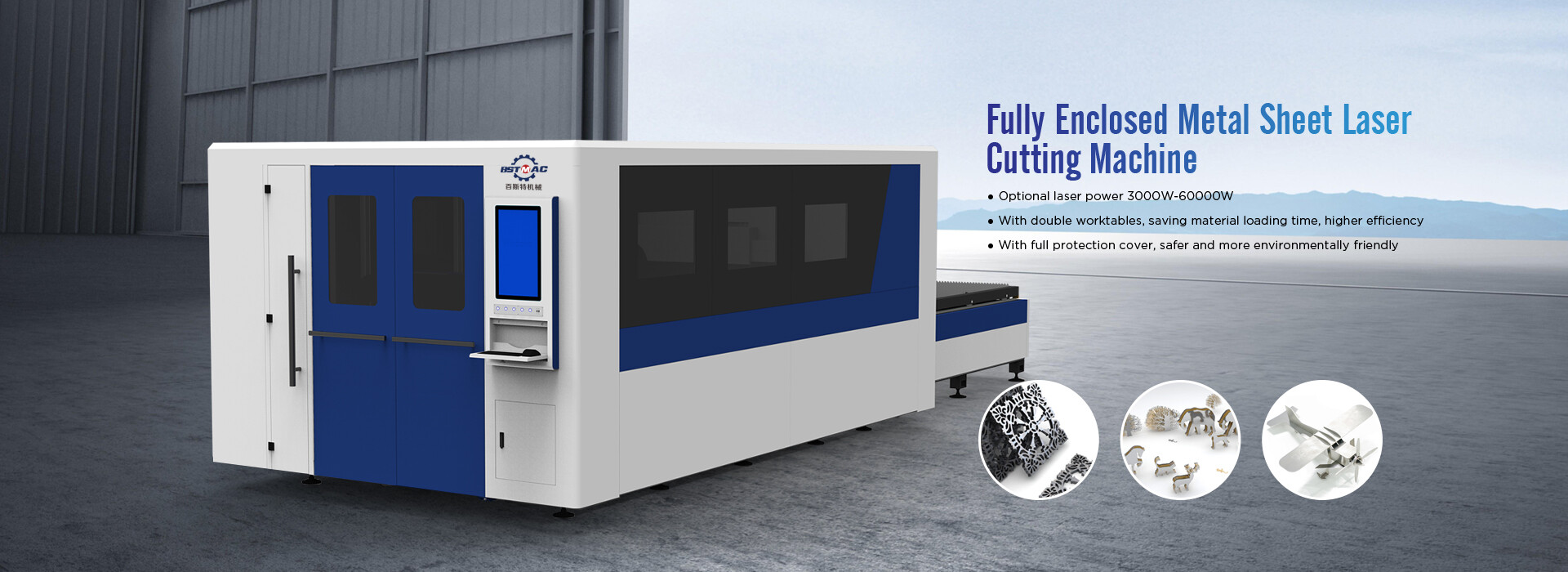

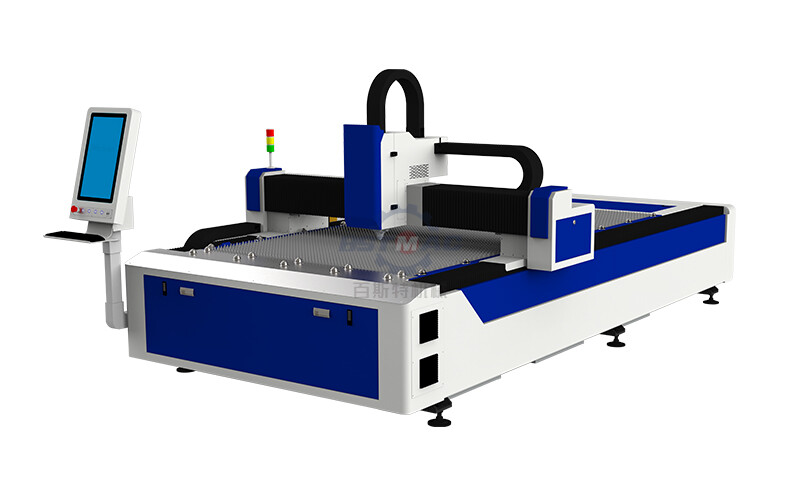

The BST-G3015C is an ideal entry-level sheet metal laser cutting machine. The extremely high price-performance ratio and simple machine operation can allow you to get payback asap.

Advantages of laser cutting machine:

Laser cutting machine replaces mechanical tools with invisible lasers.

It has the following characteristics:

* high precision

* fast cutting

* no restrictions on cutting patterns

* automatic typesetting to save materials

* smooth incisions

* low processing costs

Technical parameters

|

Model |

BST-G3015C |

|

Laser Power |

1500w/ 2000w/ 3000w/ 6000w |

|

Working Size |

3000*1500mm/ 4000*1500mm/ 4000*2000mm/ 6000*2000mm |

|

Cutting Speed |

55m/min (3000w cutting 1mm ss) |

|

Laser Wavelength |

1070nm |

|

Minimum Linewidth |

0.1mm |

|

Repeat Position Accuracy |

0.05mm |

|

Max. Cutting Thickness |

20mm (3000w for example. Cutting thickness depends on different material types and laser power.) |

|

Total Power |

12kw |

|

Machine Weight |

3600kg |

|

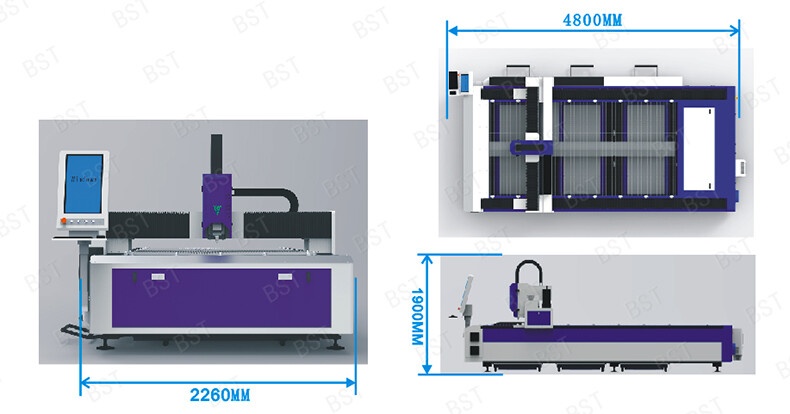

Machine Overall dimension |

4350*2230*1800mm |

|

Cooling System |

Water cooling |

|

Engineers available to provide service overseas |

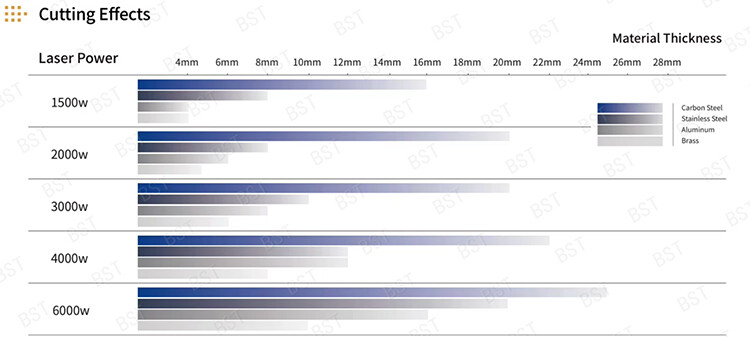

Cutting Thickness Parameters:

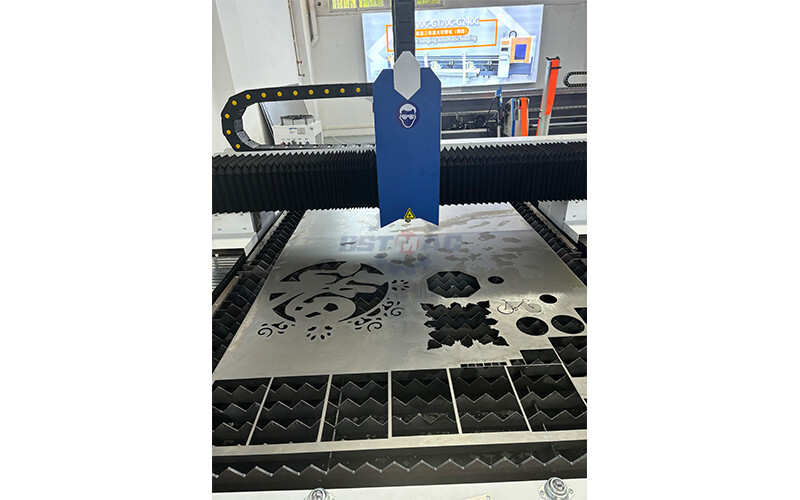

Applications and Cutting Samples:

Fiber laser cutting machines are gradually playing an important part in the metal fabrication industry. Such as metal signage, interior decoration, engineering parts, sheet metal cabinets, automobile industry, advertising industry, kitchenware industry, home appliance, elevators, doors and windows, and other industries.

Almost all materials common in the metal processing industry, steel, aluminum alloy, carbon steel, mild steel, galvanized steel, steel coil, zinc coated steel sheet, brass, stainless steel, electrolytic plate, and other ferrous and non-ferrous metals can be fastly and accurately cut by the laser cutting machine.

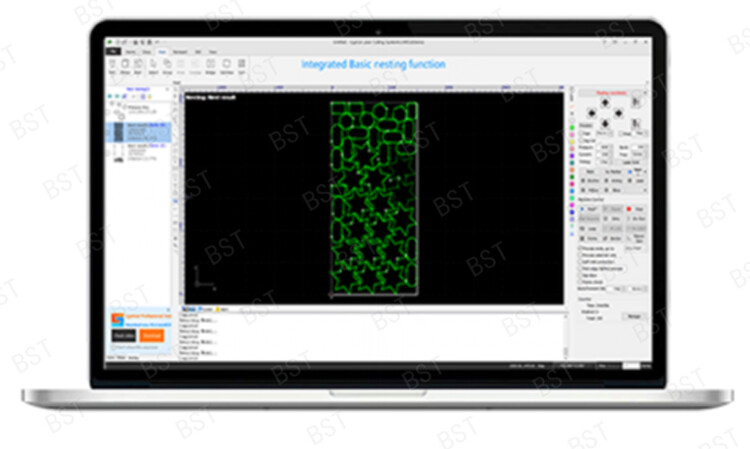

Easy Operation Cypcut Control System

> Simple and convenient operation

> User-Friendly operation interface

> Rich cutting process database for diversified cutting

Developed by the leading developers, the system provides various intelligent functions to help you free your hands in metal fabrication. Smart technology such as fly cut, common-edge cutting, micro-joint, leapfrog, centering, smart collision prevention, automatic edge seeking, etc.

Aircraft-grade Extrudded and Stretched Integrated Aluminum Crossbeam

Ultra high pressure stretching process and lightweight design;

Structural strength enhanced by 25%;

Weight goes down by 30%;

Quality Control

Machine body testing is important for checking quality of a laser machine, especially motion parts installation, which ensure running and cutting accuracy, here we introduce you how we test our laser machine.

1. Linear guide parallelism examination, our requirement ≤±0.02mm.

2. Rack installation, accuracy lower than ≤±0.02mm.

3. Guide gap detection, our requirement ≤±0.03mm.