Product Details

Machine features

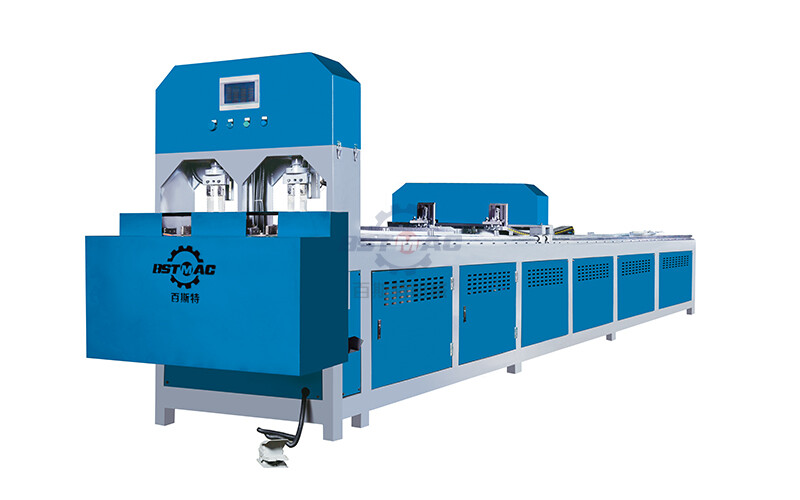

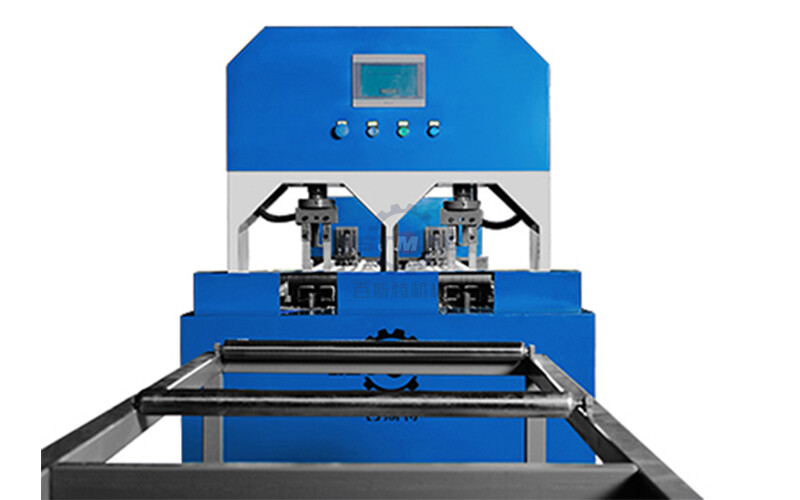

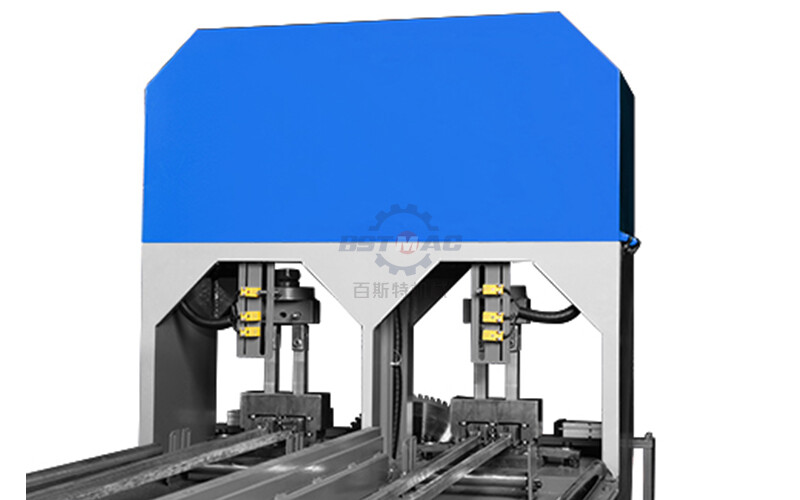

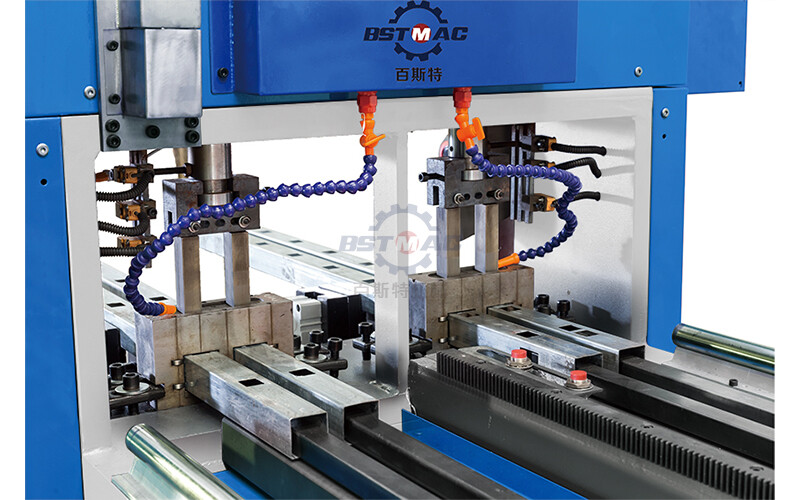

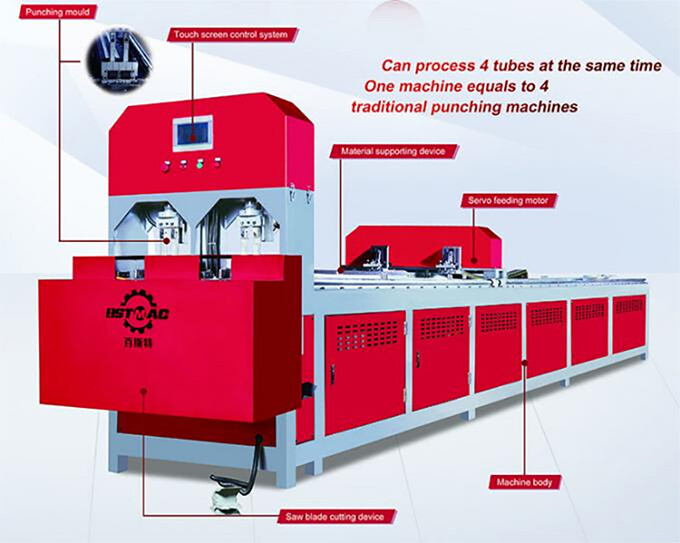

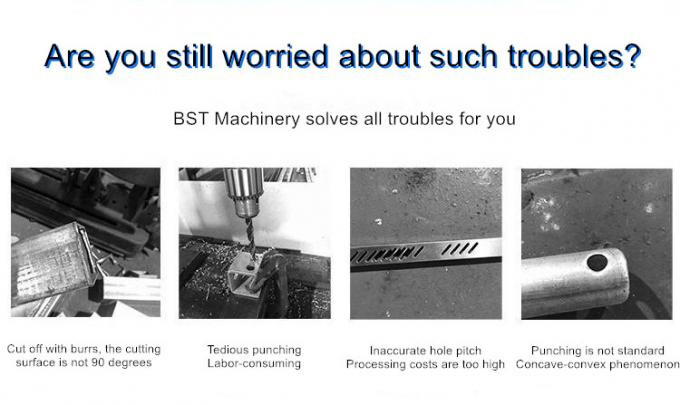

This full automatic CNC punching and cutting machine was developed on the basis of the original automatic CNC punching machine. The original two processes of punching after cutting are effectively combined into one, which reduces the cutting step, secondary handling and space. It also ensures the accuracy of the product's cutting and punching dimensions, effectively reducing the labor intensity of workers, improving production efficiency, and enhancing the competitiveness of enterprises.

Main functions

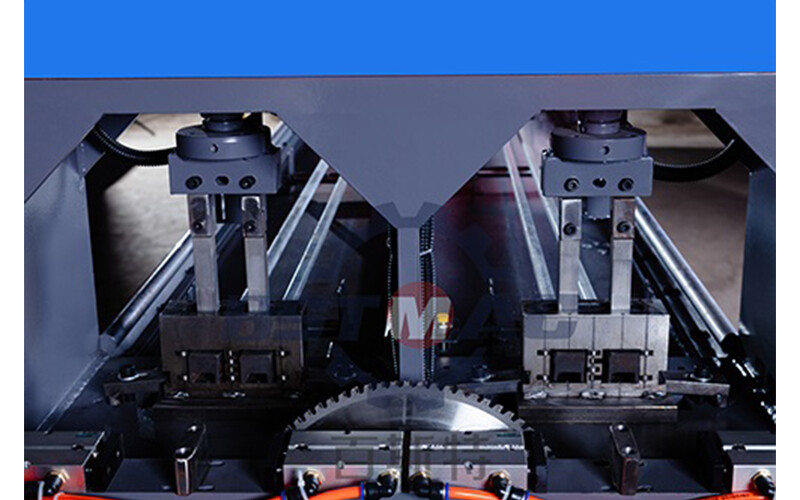

1. Full automatic CNC punching + cutting.2. Single or multiple tubes can be punched at one time.

3. It can automatically punch any hole distance on the same tube.

Technical parameters

|

Automatic CNC punching and cutting machine |

|||

|

Model |

BST-80-2-CKQG |

BST-100-2-CKQG |

BST-125-2-CKQG |

|

Hydraulic motor power |

7.5KW |

11KW |

11KW |

|

Oil cylinder specs. |

80*100mm |

100*100mm |

125*100mm |

|

Punching stroke |

100mm |

100mm |

100mm |

|

Punching force |

80Kn |

100Kn |

196Kn |

|

Max. pressure |

16Mpa |

16Mpa |

16Mpa |

|

Punching materials and objects |

Aluminum, iron, stainless steel, brass, copper, PVC tubes and profiles. Angle iron, C-shape steel, channel steel and other irregular shaped profiles. |

||

|

Profiles punching size |

Square tube: Max. 60*60mm (half hole punching), 50*50mm (full hole punching). |

||

|

Power supply |

380V-50Hz |

||

|

Control voltage |

DC24V |

||

|

Cooling method |

Forced air cooling 100L |

Forced air cooling 150L |

|

|

Control system type |

Closed loop control system |

||

|

Punching frequency |

0.3-1.5S/Time |

0.8 -2.0S/Time |

|

|

Servo system |

750W |

1KW |

|

|

Operating system |

User-friendly touch screen operation |

||

|

Touch screen |

7 inches |

||

|

Guide rail |

Linear guide rail |

||

|

Oil tank capacity |

138L |

200L |

200L |

|

Oil tank inspection port |

Available |

||

|

Oil tank drain |

Quick ball valve type |

||

|

Working light |

DC24V-LED working light |

||

|

Protection System |

Hydraulic pressure protection, voltage protection, motor phase loss and phase sequence protection, motor overheating protection |

||

|

Working length |

6000mm |

||

|

Overall dimension |

L 7000* H 1500* W 1200mm |

L 7000* H 1500* W 1200mm |

L 7000* H 1500* W 1200mm |

|

Machine weight |

2T |

2.2T |

2.5T |

|

Welcome to inquire for more details. We can provide customization services according to customers' needs. |

|||

Processing samples

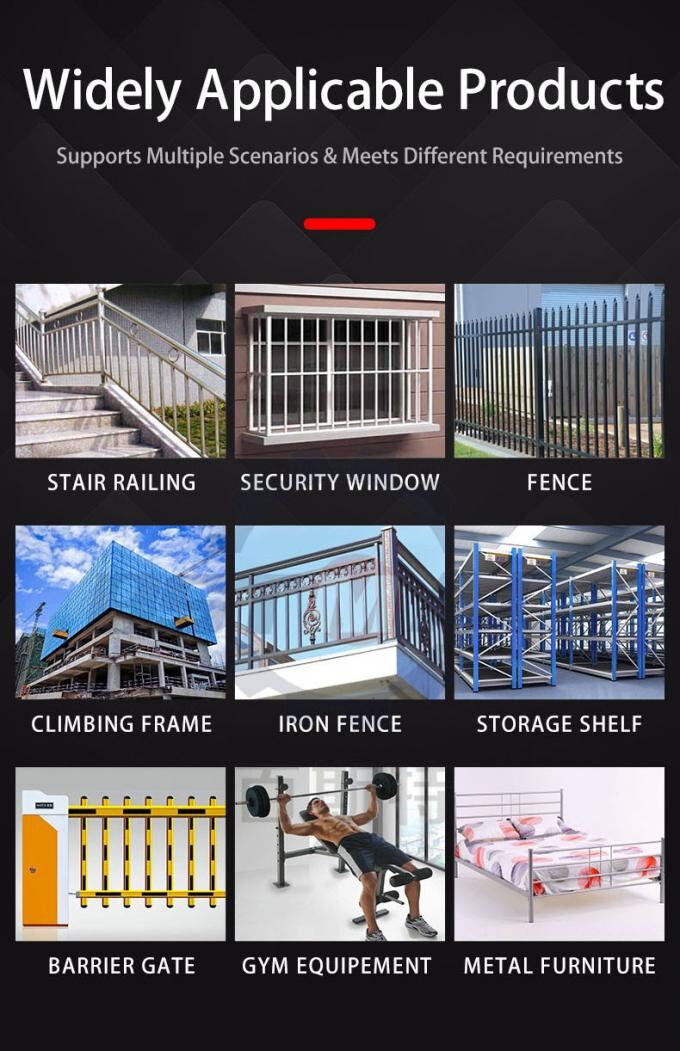

Application industries

FAQ

A: You have to inform us the following details:

- The tube shape and size – including wall thickness.

- Material to be punched

- The maximum tube length

- The shape and size of the hole(s) to be punched

- The distance between each hole, how many holes and where they are located in the tube.

- The drawings if possible

A: It's fast. Skilled operator can finish within 10 minutes.

A: Our machine warranty is one year, and we use all the stable components with long working life!

A: We are a manufacturer, we are dedicated to metalworking machines manufacturing.

A: EXW / FOB / CNF / CIF / DDU / DDP.

A: Strict quality control, vision inspection one by one before packing.